Geosynthetic Excellence: Unraveling the Benefits of Progressive Die Stamping in Metal Manufacturing

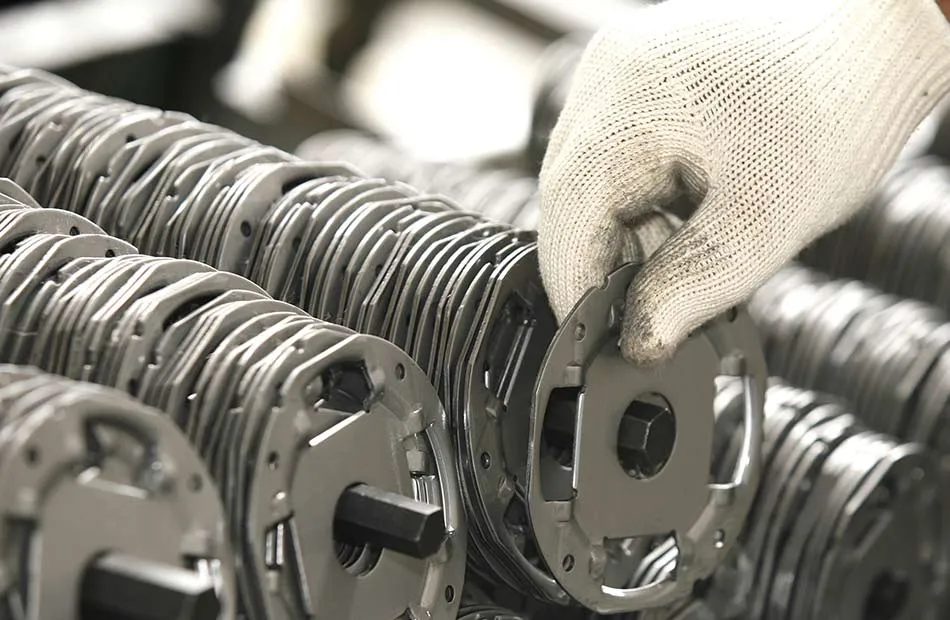

Metal stamping stands as a cost-effective manufacturing method that utilizes pressure, die surfaces, and tooling to produce precision metal components in large quantities. This high-speed metalworking process encompasses various cold-forming techniques like bending, cutting, blanking, punching, and coining that shape a workpiece from sheet metal.

In the realm of the geosynthetic industry, metal stamping techniques play a crucial role, with progressive die stamping and four-slide stamping emerging as two cost-effective options. Both methods offer unique advantages, making them well-suited for crafting diverse components tailored to the geosynthetic sector.

- Progressive Die Stamping with Geosynthetic Precision

Progressive die stamping, a method employing multiple stations for successive tasks, ensures accuracy and efficiency in the geosynthetic manufacturing process. The connective stock strip moves into a die press from a coil, transporting metal workpieces horizontally between stations where they undergo cutting, punching, or bending tasks. Geosynthetic manufacturers benefit from progressive die stamping due to its inherent accuracy, efficiency in producing complex parts, long die lifespan, rapidity, and reduced overall costs.

- Four-Slide Stamping for Geosynthetic Versatility

Four-slide stamping, another geosynthetic-friendly technique, forms metal into designated shapes using four tools that move laterally simultaneously. The comprehensive operations of four-slide stamping offer a start-to-finish procedure, eliminating the need for secondary operations. Geosynthetic applications benefit from the design and material versatility of four-slide stamping, enabling the creation of intricate and unique configurations in a cost-effective manner. Additionally, its adaptability facilitates efficient modifications for new components, resulting in faster turn times and overall cost-effectiveness.

- Cost-Effective Metal Stamping Solutions at ESI for the Geosynthetic Industry

Progressive die stamping and four-slide stamping, proven and reliable techniques in the geosynthetic landscape, find an efficient home at Engineering Specialties, Inc. (ESI). As a trusted provider of cost-effective, IATF-certified stamping services, ESI employs advanced automation equipment, ensuring tight tolerances and superior custom results for the geosynthetic industry. If you seek precision and affordability in geosynthetic metal stamping, reach out to ESI today to request a quote and embark on your next project with confidence.