How to Troubleshoot Common Issues with a BNA Range Pump

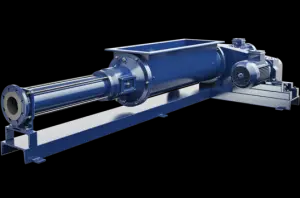

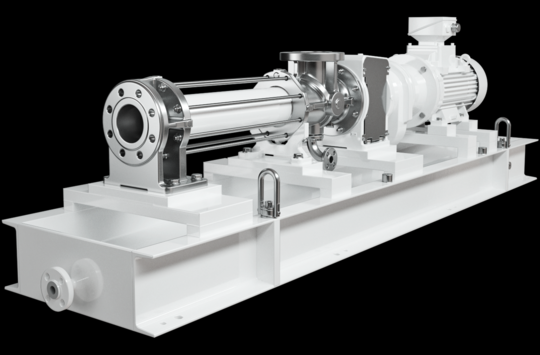

BNA range pumps are essential components in various applications, providing reliable fluid transfer and pressure maintenance. However, like any mechanical system, they can experience issues that may hinder their performance. Understanding how to troubleshoot these common problems can help maintain efficiency and prolong the pump’s lifespan.

Identifying Common Issues

Before diving into troubleshooting, it’s important to recognize the signs that indicate your BNA range pump may be facing issues. Common symptoms include:

- Unusual noises during operation

- Fluctuating pressure readings

- Reduced flow rate

- Leakage around the pump

- Overheating

Step-by-Step Troubleshooting Guide

Here’s a structured approach to diagnosing and resolving issues with your BNA range pump:

1. Inspect for External Damage

Start by examining the pump for any visible signs of damage. Check for cracks, loose fittings, or worn-out seals. External damage can lead to leaks and reduced efficiency, so addressing these issues is crucial.

2. Check Power Supply

Ensure that the pump is receiving adequate power. Inspect the electrical connections and confirm that there are no loose wires or blown fuses. A stable power supply is essential for the pump to function properly.

3. Monitor Operating Conditions

Evaluate the operating conditions of the pump. Ensure that it is being used within its specified parameters for temperature, pressure, and fluid type. Operating outside these limits can cause performance issues and even damage the pump.

4. Examine the Fluid Path

Inspect the inlet and outlet pipes for blockages or restrictions. Any obstruction can significantly affect the flow rate and pressure. Clean or replace any clogged filters and ensure that the piping is free of debris.

5. Listen for Unusual Noises

Pay attention to any abnormal sounds coming from the pump. Grinding, rattling, or whining noises can indicate mechanical issues such as bearing wear or misalignment. If you hear these sounds, it may be necessary to disassemble the pump for further inspection.

6. Check for Leaks

Look for any signs of leakage around the pump and its connections. Leaks can be caused by damaged seals or loose fittings. Tighten connections as needed and replace any damaged components to prevent further leakage.

7. Assess Temperature Levels

An overheating pump can indicate several issues, including insufficient lubrication or excessive friction. Check the lubrication levels and ensure that the pump is not operating under extreme conditions. If overheating persists, consider consulting the manufacturer for guidance.

Conclusion

Troubleshooting a BNA range pump requires a systematic approach to identify and resolve common issues. By inspecting for damage, checking the power supply, monitoring operating conditions, examining the fluid path, listening for unusual noises, checking for leaks, and assessing temperature levels, you can effectively maintain your pump’s performance. Regular maintenance and prompt attention to issues will not only enhance the longevity of your BNA range pump but also ensure its efficient operation in your applications.