Progressive Die Stamping Process: Enhancing Efficiency and Quality with Geotextile

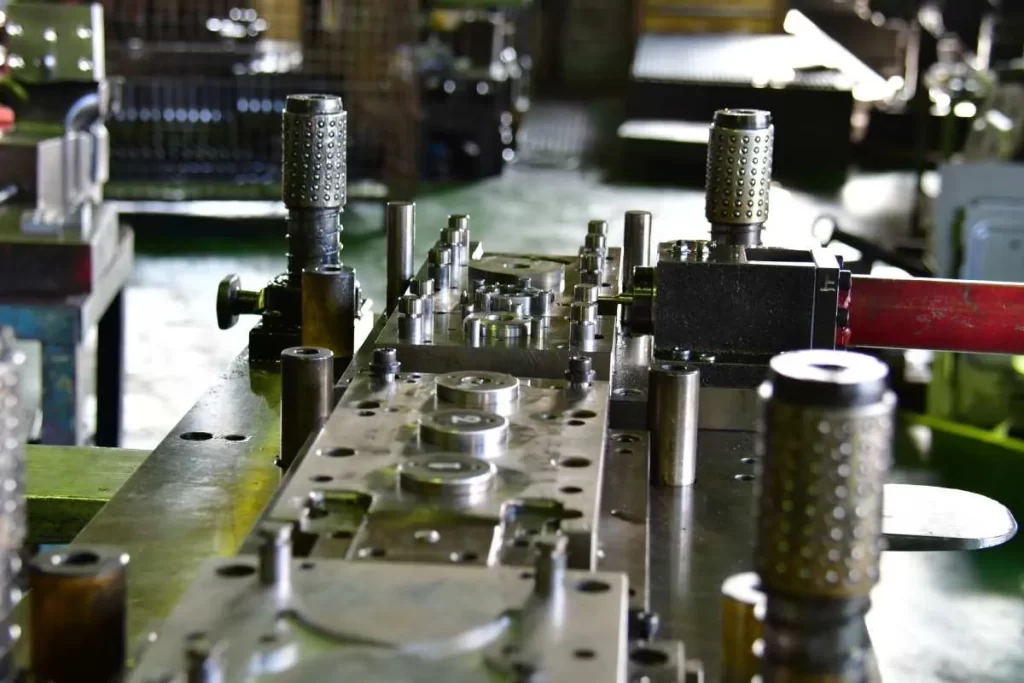

The progressive die stamping process is a highly efficient method of shaping and fabricating materials into durable parts for various industries. By incorporating geotextile materials, manufacturers can further enhance the efficiency and quality of the process.

Progressive Die Stamping Process with Geotextile

In the standard progressive die stamping process, geotextile materials can be utilized at various stages to optimize performance:

- Improved Die Functionality: When positioning the progressive die into the stamping press, geotextile materials can be integrated to ensure proper opening and closing functionality. This enhances the overall efficiency of the process.

- Enhanced Metal Strip Feeding: Geotextile materials can be incorporated into the feed system to facilitate the smooth movement of metal strips between workstations. This integration reduces friction and enhances the accuracy of the feeding process.

- Automation and Material Removal: Geotextile materials can be utilized in stamping dies to automate the removal of excess material. This not only increases efficiency but also reduces waste, resulting in cost savings.

- Precision and Quality Control: Geotextile materials can contribute to the design and layout of the stock strip, optimizing the position of punches, bends, and holes. This level of precision ensures consistent part repeatability and high-quality production.

- Durability and Dimensional Stability: Geotextile materials can undergo secondary processes such as heat treating, which improves the durability and dimensional stability of the parts. This is particularly beneficial for parts that require higher strength and longevity.

Maximizing Efficiency with Geotextile in Progressive Die Stamping

By incorporating geotextile materials into the progressive die-stamping process, manufacturers can achieve the following benefits:

- Increased Production Efficiency: Geotextile materials reduce friction and improve the feeding process, allowing for higher production speeds and improved productivity.

- Cost Savings: The automation enabled by geotextile materials reduces material waste, leading to cost savings in production.

- Enhanced Part Quality: Geotextile materials contribute to precise part repeatability, resulting in consistent high-quality parts.

- Improved Durability: Geotextile materials, along with secondary processes like heat treating, enhance the durability and longevity of the stamped parts.