The Importance of Valves in Modern Engineering Systems

Valves play a critical role in controlling the flow of liquids, gases, and other materials in both industrial and residential systems. Their applications range from simple faucets to complex industrial processes. This article explores the different types of valves, their functions, and the integration of geotextiles in engineering.

Types of Valves and Their Uses

Valves come in various forms, each tailored for specific functions. Major types include:

- Gate Valves: Ideal for on/off control in pipelines requiring minimal flow restriction.

- Ball Valves: Known for their reliability and durability, used in plumbing.

- Globe Valves: Used for flow regulation, offering better throttling capabilities.

- Check Valves: Prevent backflow, crucial for maintaining one-directional flow in systems.

- Butterfly Valves: Lightweight and requiring less structural support, used for isolating or regulating flow.

Selecting the appropriate valve type is essential for system efficiency.

Mechanisms of Valve Operation

Valves function by opening, closing, or partially obstructing passageways. Their mechanisms involve a movable element, such as a disc or plug, that adjusts to control flow. Examples include:

- Manual Valves: Operated manually with levers or wheels.

- Automated Valves: Controlled by electric, hydraulic, or pneumatic systems.

The operation method is chosen based on application needs, such as remote control or frequency of operation.

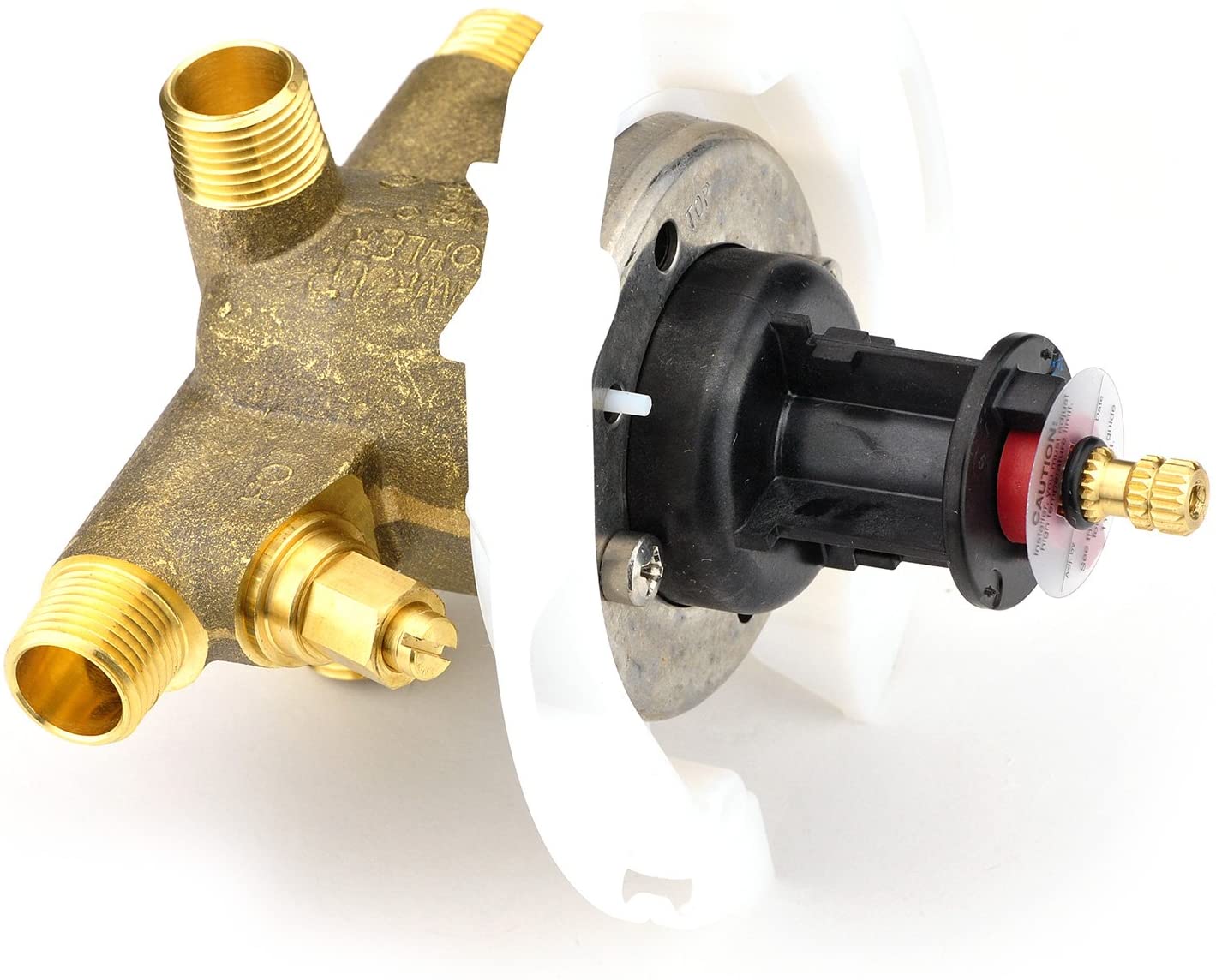

Materials Used in Valves

Valves are made from various materials, chosen based on their application and the nature of the fluids they manage. Common materials include:

- Brass: Durable and corrosion-resistant, used in residential water systems.

- Stainless Steel: Suitable for high-pressure, high-temperature environments, offering excellent corrosion resistance.

- PVC: Ideal for low-pressure, low-temperature applications, especially in chemical processing.

- Cast Iron: Common in industrial applications for its robustness.

Choosing the right material ensures the valve’s longevity and efficiency.

Integration of Valves and Geotextiles in Engineering

Valves and geotextiles often intersect in fluid management systems. Geotextiles are permeable fabrics used for soil stabilization, erosion control, and drainage. Examples of their integration include:

- Landfill Leachate Management: Valves regulate leachate flow, while geotextiles provide filtration and drainage.

- Stormwater Management: Valves control water flow, and geotextiles prevent soil erosion and enhance filtration.

- Irrigation Systems: Valves manage water distribution, and geotextiles maintain soil stability and proper water flow.

This integration improves the efficiency and sustainability of infrastructure projects.

Valves are versatile and essential in numerous applications, from simple home plumbing to complex industrial systems. Understanding their types, mechanisms, materials, and their relationship with geotextiles is crucial for optimizing their use. As technology evolves, these components will continue to support efficient and sustainable engineering solutions.