Geocell Metal Stamping vs. Metal Fabrication: Understanding the Differences

When it comes to manufacturing metal parts and components, some applications may utilize either sheet metal stamping or other metal fabrication processes. However, it’s important to note that these terms, “sheet metal stamping” and “metal fabrication,” are often used interchangeably, despite referring to distinct manufacturing processes with significant differences.

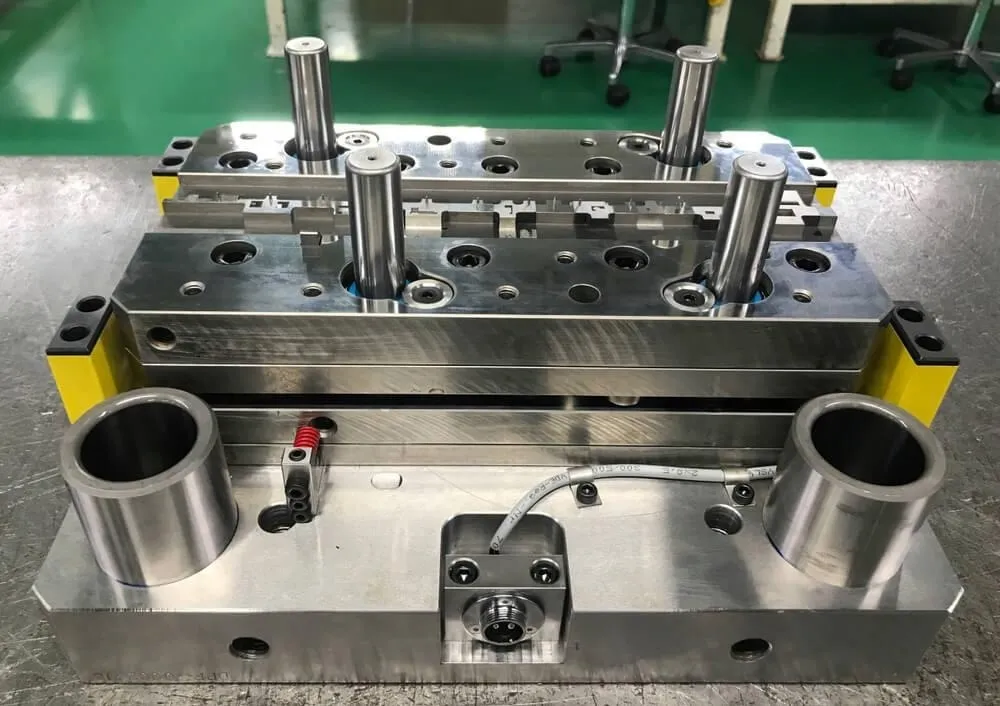

Sheet metal stamping, which is a form of metal fabrication, involves the use of dies, punches, and various tools to shape the sheet metal into the desired end component. This cost-effective process is particularly suitable for large production runs and can be carried out as a single or multiphase process. In the case of multiphase or progressive die stamping, a strip of metal is pulled through a tool, with each tooling station performing different punches, cuts, or bends. As the part progresses through the process, each station contributes to the work of the previous one, resulting in a completed product at the end of the run.

The advantages of metal stamping, including sheet metal stamping, include a lower cost per piece for larger production runs, the capability to create complex designs, high repeatability, and the availability of secondary processing options. If you require parts manufactured in large quantities, sheet metal stamping, such as Geocell sheet metal stamping, can be a beneficial choice over metal fabrication. However, it’s worth considering metal fabrication for other applications, such as the production of one-off products. Additionally, it’s important to note that stamping costs may accumulate due to tooling expenses and longer preparation periods.

Moving on to metal fabrication, it is a broad term that encompasses various manufacturing processes, such as cutting, bending, and punching. Metal fabrication typically involves more labor-intensive practices and longer production times. This process focuses on shaping metal parts by either removing or changing materials. For example, some metal fabrication processes may involve creating cutouts or holes in metal materials, while others may alter the shape of the metal through stretching and bending.

The advantages of metal fabrication, including Geocell metal fabrication, include rapid prototyping, versatile fabrication techniques like laser cutting and shearing, diverse customization options, and quick and easy design adjustments. While sheet metal fabrication is well-suited for many metal manufacturing applications, it requires more labor and longer production periods compared to sheet metal stamping. Additionally, the costs of materials tend to be higher in fabrication, and it may not be feasible to fabricate parts with more complex designs.

Another drawback of metal fabrication is its limited repeatability, making it less compatible with high-volume production runs. However, metal fabrication can provide a cost-effective and efficient solution for applications requiring the low-volume production of pieces with simpler designs.

When making a decision between sheet metal stamping and metal fabrication, it’s crucial to consider factors such as production volume, design complexity, cost constraints, and time requirements. By understanding the differences between these processes, you can make an informed decision and choose the most suitable method, whether it be Geocell sheet metal stamping or Geocell metal fabrication, for your specific manufacturing needs.